ТОП просматриваемых книг сайта:

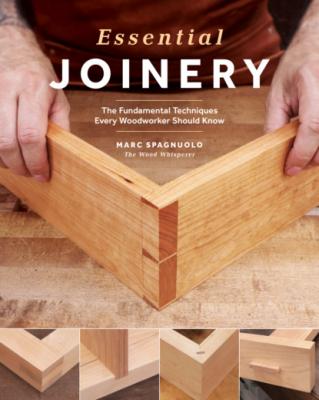

Essential Joinery. Marc Spagnuolo

Читать онлайн.Название Essential Joinery

Год выпуска 0

isbn 9781951217167

Автор произведения Marc Spagnuolo

Жанр Сделай Сам

Издательство Ingram

consider constructing a shop-made cradle. A cradle provides safe and

repeatable results.

TOOLS

Adjustable square

Drill

Countersinking drill bit

and driver

Clamps

1. You’ll need four pieces of

sheet good stock to make the

cradle. The type of sheet good

isn’t critical—MDF or plywood

are both good choices. The

dimensions are also not critical;

shown are two center pieces at

7 x 11" and sides at 8 x 16". Glue

the two center boards together

at a right angle.

2. Pilot-drill and countersink

screws to hold the center

boards together.

TIP

Countersink bits are often

too short to drill the pilot

hole fully into the adjoining piece.

I like to use a separate drill bit to

increase the depth of the pilot hole.

36

ESSENTIAL JOINERY

REINFORCING FLAT MITER JOINTS | Butt Joints

3. On the inside of the center

pieces, clearly mark the locations

of the screws to remind yourself

not to cut through them later.

4. On the side pieces, draw

two 45° lines from the center

point.

5. Pilot-drill and countersink for

screws about ⅜" inside of the

pencil lines.

3

4

5

37

ESSENTIAL JOINERY

Butt Joints | REINFORCING FLAT MITER JOINTS

6

7

8

9

6. Make a glue line on the inside

of one of the side pieces and drop

the center piece in place.

7. Clamp the center piece in

place.

8. Drive screws into the

drilled holes, making sure they’re

countersunk below the face of the

stock.

9. Apply a bead of glue to

the other side and attach it

with screws.

38

ESSENTIAL JOINERY

REINFORCING FLAT MITER JOINTS | Butt Joints

10. Turn the jig upside down

and mark the desired center

point for the key. On a ¾" piece,

this would be ⅜" in from the

inside face of the jig.

11. Use the pencil line to locate

the fence and jig relative to the

blade.

12. Depending on your screw

placement, you may want to

remove the lowest screws on the

fence side of the jig to avoid any

contact with the blade.

13. Clamp the glued-up frame

to the side of the jig with the

corner fully seated in the cradle,

raise the blade to the desired

height, and make the cut.

10

12

13

11

39

ESSENTIAL JOINERY

Butt Joints | REINFORCING FLAT MITER JOINTS

1

2

3

CUTTING + INSTALLING KEYS

Regardless of the method you use for cutting a key slot, the process

for milling and installing the key itself is the same.

TOOLS

Bandsaw

Handplane or drum sander

Clamps

Flush trim saw

Sanding block or

handplane

1. Resaw a piece of stock to just

proud of the desired thickness.

The bandsaw can leave a rough

cut, so you’ll want an opportunity

to smooth the surface while

bringing it down to the perfect

thickness.

2. Smooth the thin strip at the

workbench with a handplane.

Keep working until the piece fits

into the key slot perfectly.

3. A drum sander is a great

power tool alternative to smooth

and thickness the key stock.

40

ESSENTIAL JOINERY

REINFORCING FLAT MITER JOINTS | Butt Joints

4. The key should slide in easily

since it tends to swell once glue is

added.

5. The key stock can then be cut

into slightly oversized triangles.

The grain should be oriented so

it runs perpendicular to the miter

joint in the frame.

4

5

41

ESSENTIAL