ТОП просматриваемых книг сайта:

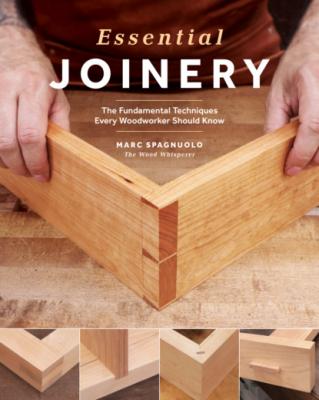

Essential Joinery. Marc Spagnuolo

Читать онлайн.Название Essential Joinery

Год выпуска 0

isbn 9781951217167

Автор произведения Marc Spagnuolo

Жанр Сделай Сам

Издательство Ingram

2. Lay out and drill pocket holes

following the manufacturer’s

instructions on the non-show

face. Place at least two screws per

joint if possible.

3. Apply clamping pressure

to the assembled joint so the

boards don’t shift. Glue is

optional, but doesn’t hurt.

TIP

Avoid screwing into end

grain. The pockets are

usually drilled in such a way that the

screw itself is biting into edge or

face grain when the joint is pulled

together. Screws are weak when

driven into end grain.

15

ESSENTIAL JOINERY

Butt Joints | FRAME BUTT JOINT USING POCKET SCREWS

4. Pocket screw companies

make handy clamps that help

keep the joint nice and flush.

These can be used in addition

to the regular clamp.

5. Drive the screws into place.

The screw helps close up the

joint.

6. This joint is easy to make

and surprisingly strong.

4

5

6

16

ESSENTIAL JOINERY

FRAME BUTT JOINT USING DOWELS

Another option for connecting frame parts is dowel joinery. Holes are drilled on

both workpieces and premade dowels are inserted with glue. Dowels have the

additional benefit of being completely hidden.

1

4

2

3

TOOLS

Dowel jig

Drill

Drill bit

Clamp

1. Arrange the parts to be

joined and mark the dowel

locations across the joint.

2. There are many dowel jigs

on the market, but self-centering

dowel jigs are the most useful.

3. Align the desired hole size

with the lines on one of the

workpieces and secure the jig.

4. Drill in the hole using the

desired drill size with blue tape

wrapped around the bit serving as

a depth stop.

17

ESSENTIAL JOINERY

Butt Joints | FRAME BUTT JOINT USING DOWELS

5. Move the jig to the remaining

holes and repeat the drilling

process.

6. Repeat the drilling process on

the adjoining workpiece.

7. Insert dowels into each hole.

For a more permanent

connection, add glue and

clamping pressure.

6

7

5

TIP

You can make your own

dowels using a simple device

known as a dowel plate (a thick piece

of steel with various common sized

holes in it). Scrap wood can be cut

or riven slightly oversized and then

pounded through a dowel plate

to create dowels of the

desired diameter.

18

ESSENTIAL JOINERY

FRAME BUTT JOINT USING DOWELS | Butt Joints

ALTERNATIVE METHODS

HOMEMADE DOWEL JIG ALTERNATIVE

A dowel jig is a nice convenience and offers increased accuracy and repeatability, but it is certainly

possible to save a few bucks and make a shop-made doweling jig out of scrap wood.

1

2

3

1. Lay out the desired hole

locations on a thick piece of

scrap. Keep in mind, because

this jig is made of wood, the

holes will eventually wear out.

Consider it disposable.

2. Drill the holes as straight

and true as possible. Keep a

large square nearby to give a

visual reference.

3. Glue another piece of

scrap to the reference side of

the block to serve as a stop.

19

ESSENTIAL JOINERY

Butt Joints | FRAME BUTT JOINT USING DOWELS

4. To use the jig, simply clamp

it to the board, lining up the

reference marks with the drill

locations on the workpiece, and

drill away.

5. After drilling the dowels in

the adjoining piece, glue and

assemble as per usual.

4

5

20

ESSENTIAL JOINERY

FRAME BUTT JOINT USING DOUBLE BISCUIT

Biscuits can make quick work of frame assembly, but for some applications, a single

biscuit just doesn’t seem strong enough. So let’s add two biscuits