ТОП просматриваемых книг сайта:

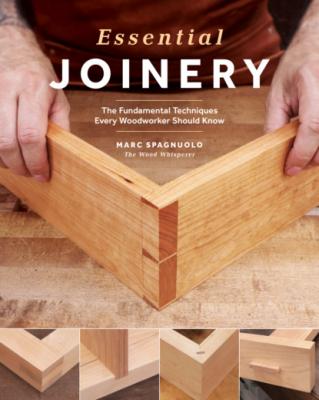

Essential Joinery. Marc Spagnuolo

Читать онлайн.Название Essential Joinery

Год выпуска 0

isbn 9781951217167

Автор произведения Marc Spagnuolo

Жанр Сделай Сам

Издательство Ingram

Chapter 1

BUTT JOINTS

In its simplest form, joinery is nothing more than a method

for attaching one piece of wood to another. There’s no more

fundamental example of that than the humble 90° butt joint.

My very first woodworking projects featured butt joints; I still

use them today when the project calls for it. As you progress in

your woodworking journey, you will likely move on to some of

the more involved joints covered later in this book, but this is

where it all begins.

It’s important to note that a simple glued 90° butt joint is

inherently weak. The end grain of one of your boards will soak

up most of the glue, rendering the joint ineffective. This is why

much of this chapter focuses on reinforcement methods for

each joint.

10

ESSENTIAL JOINERY

SCREW-REINFORCED 90° BUTT JOINT

One of the most accessible ways to reinforce a basic 90° butt joint is to add screws.

The screws not only hold the pieces tightly together but also add reinforcement

because the screw penetrates both workpieces.

1. Cut parts to desired size. It is

critical that the ends are nice and

square.

2. Though there are many other

options for squaring stock, a

tablesaw outfitted with a miter

gauge or cross-cut sled makes it

quick work.

1

2

TOOLS

Square

Tablesaw

Miter gauge or cross-cut sled

Clamp

Drill with countersink bit

Bandsaw or plug cutter

Mallet

Flush trim saw

Plane or sanding block

11

ESSENTIAL JOINERY

Butt Joints | SCREW-REINFORCED 90° BUTT JOINT

3

4

5

6

3. Apply glue to the end grain

and the face or edge of the

adjoining piece. While the glue

won’t add a tremendous amount

of strength, I never let my joints

go naked.

4. Confirm the workpieces are

square and adjust the clamp if

needed.

5. Use an adjustable

countersink bit to pilot-drill the

screw hole while also creating a

nice deep recess for a wood plug.

6. Drill at least two holes per

joint. Since these will be visible

in the final product, take care to

arrange the holes so they are

visually pleasing.

12

ESSENTIAL JOINERY

SCREW-REINFORCED 90° BUTT JOINT | Butt Joints

7. Drive a screw into each

hole and remove the clamp.

8. To cap off the screws, you can

use a short length of dowel rod

(typically ⅜").

9. For end-grain plugs (like

those cut from a dowel), apply

glue to the holes and the plugs

and tap them into place.

7

8

9

13

ESSENTIAL JOINERY

Butt Joints | SCREW-REINFORCED 90° BUTT JOINT

10

11

12

10. A better alternative is

to use a tapered plug cutter. Drill

into a piece of solid stock and pop

out the plug with a screwdriver.

11. For a tapered plug (from the

plug cutter), be sure to align the

grain of the plug with the grain of

the workpiece. Then comes the

most exciting portion of any joint

assembly: wait for the glue to dry.

12. Once the glue is dry, saw off

the excess using a flush trim saw

and either plane or sand smooth.

In the last photo, you can see the

visual difference between an end-

grain dowel (darker, on the left)

and the face-grain piece from the

plug cutter (almost invisible, on

the right).

14

ESSENTIAL JOINERY

FRAME BUTT JOINT USING POCKET SCREWS

Pocket screws can make frame assembly quick and easy. Just cut your parts to

length, drill the holes, and drive the screws. It’s very common to see cabinet doors

assembled with pocket screws.

3

1

2

TOOLS

Drill

Drill bit and driver

Pocket hole jig

Clamps

1. Arrange the parts to be

jointed and