ТОП просматриваемых книг сайта:

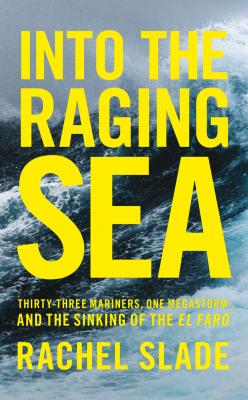

Into the Raging Sea: Thirty-three mariners, one megastorm and the sinking of El Faro. Rachel Slade

Читать онлайн.Название Into the Raging Sea: Thirty-three mariners, one megastorm and the sinking of El Faro

Год выпуска 0

isbn 9780008302450

Автор произведения Rachel Slade

Издательство HarperCollins

A logistics company’s most valuable assets, along with the cargo and the people aboard, are its vessels. Why wasn’t anyone at TOTE following them? One shipping company operator I spoke to said he considers the ships his children. He follows them constantly as they motor around the world. Denmark-based Maersk, among the world’s biggest shippers, doesn’t just follow its vessels’ tracks. It also installs cameras and microphones in the engine room, on the bridge, and in the cargo holds, which send video and audio back to the main office in real time. This information can help the Maersk managers quickly identify, solve, and even prevent problems. TOTE had no such monitoring equipment aboard El Faro.

TOTE’s reply to Davidson’s request finally came in more than five hours later—a simple, “Captain Mike, diversion request through Old Bahama Channel understood and authorized. Thank you for the heads up. Kind regards.” The email came from Jim Fisker-Andersen, director of ship management for TOTE, who was traveling back to his Jacksonville office from San Francisco, after overseeing some issues with the new LNG ship.

Why did Fisker-Andersen decide to reply to Davidson’s email? “Because there was an unanswered question that I didn’t want to leave open ended. I didn’t want the email to go unanswered,” he later told investigators.

When he was asked where Captain Lawrence was during that time, he said, “I don’t know.”

Did anyone onshore at TOTE track ships, Fisker-Andersen was asked. “No,” he said.

At least one person was tracking El Faro, though: Second Mate Charlie Baird.

From his South Portland home, he was glued to the Weather Channel that day. And with his girlfriend’s help, he was able to follow El Faro via her AIS (automatic identification signal) over the web. He watched in horror as she continued her course straight toward Hurricane Joaquin. Charlie sat all day on that sofa hoping against hope that someone on board had enough sense to turn the ship around.

Hull number 670 was born in Chester, Pennsylvania, on November 1, 1974. Christened Puerto Rico, it would be one of the last ships to be built at Sun Ship.

Don’t bother trying to find the Sun Shipbuilding and Dry Dock shipyard. There’s nothing left of the towering steel frames that once cradled ships while they were under construction, or the steel sheds that sheltered the pipe shop, the blacksmith shop, carpenter shop, and sheet metal shop. Nearly everything was leveled in 2004 to make way for Harrah’s Philadelphia Casino and Race Track. Where thousands of people built ships in a frenzy that lasted half a century, there’s now a five-eighths-mile elliptical track for thoroughbreds to race around a neatly kept lawn. You can bet on the horses or lose your savings at the blackjack tables inside, but you probably won’t be able to make out the skeletal remains of the towering shipways, now cut down to nubs, sulking at the water’s edge across the track from the casino.

Pull over to the grassy shoulder along Route 291 outside of the casino and you’ll notice a small cast-iron historical marker erected in 2007. It reads: “During WWII, Sun was the largest single shipyard in the world, with over 35,000 employees. It introduced the all-welded ship, which significantly increased ship production, and the T-2 oil tanker. Sun built over 250 WWII tankers, 40% of those built in the world and repaired over 1,500 war-damaged ships. Established by the Pew family, it was located at this site from 1916 to 1982.”

In the summer of 1961, twenty-year-old John Glanfield was looking for work. Tall, slim, with a wide-open face and a meaty handshake, he’d graduated from high school a few years earlier and, being mechanically minded, was thinking about fixing cars for a living. Most of his classmates had left town to serve in the armed forces but John felt compelled to stay close to home outside of Philadelphia and help his mother.

The Glanfields hadn’t had it easy. John’s father, orphaned and raised by German nuns in New Jersey, had served in Europe during World War II where he suffered a chemical weapon attack. He spent the next seven years in a hospital, lost a lung, and never fully recovered. He died the year John graduated from high school.

Growing up in Collingdale, Pennsylvania, John was bound to discover shipbuilding sooner or later. Fewer than three miles away on the banks of the Delaware River—the same river that General George Washington had crossed during an icy winter to surprise the British and win the Battle of Trenton—was Sun Shipbuilding and Dry Dock Company, the country’s largest shipyard. One day, John hopped on his bike and pedaled out to the Delaware River where he was immediately offered a job at the busy shipyard. The pay wasn’t great, but the future opened wide.

Sun Ship was a tight, mature operation at a moment of intense innovation. As soon as he saw the gigantic steel hulls under construction, and the four thousand people employed to paint, weld, rivet, and outfit them, John was hooked. “I can remember my first day walking up the gangplank onto a ship that was only partially built,” he told me. “It had the double bottom part of the side shell and there were all these guys in the engine room and all these planks and staging. And it was like, oh my God, I just love this. I was in love with the thing right off the bat.”

For a twentysomething guy with nothing but a high school degree, Sun Ship offered the opportunity to be part of something big, a chance to grow. John apprenticed as a pipe fitter and worked his way up, taking small salary bumps as he went, earning a few more dollars each year for his young family, until he was overseeing the work of dozens of men. Sun Ship took care of its supervisors, providing a complimentary hot lunch to all managers like him. On Thanksgiving, the company gave every single worker a turkey and $25.

Sun Ship’s own history followed the victories and setbacks of America itself. It was founded during World War I by two brothers, J. Howard and Joseph N. Pew, now better known as the progenitors of the Pew Charitable Trust. The brothers had inherited the seeds of a great fortune from their father, Joseph Newton Pew, who had bet big on the industrialization of a nation emerging from the ravages of the Civil War.

In the late nineteenth century, Washington, DC, finally unfettered by the demands of the agrarian south, financed the railroads, canals, and skyscrapers that would drive a new economy. Joseph Newton Pew invested in the lifeblood of industry: energy. He bought up Texan oil fields and tapped into natural gas veins in the backwoods of his native Pennsylvania. Like Andrew Carnegie and John D. Rockefeller (who’d eventually do business with him), he profited not just from government investment but also from the seemingly endless waves of immigrants pouring in from Europe and Asia who were willing to work for little pay and even fewer labor protections.

Joseph Newton Pew died in 1912, leaving Sun Oil Company (later Sunoco), in the hands of his highly educated sons. By 1916, the pair agreed to take over their entire energy distribution chain by building the hulking tankers necessary to transport their liquid gold from their oil fields in Galveston, Texas, to their refineries near Philadelphia, and then around world.

On October 30, 1917, a few months after the US entered World War I, Sun Ship’s first vessel, a 430-foot tanker christened Chester Sun, was launched off the banks of the Delaware River. “In spite of the terrific downpour,” J. Howard Pew told the Philadelphia Inquirer the next day, “everything went as smoothly as clockwork. We wouldn’t postpone the launching, for the superstition of the sea has it that if a launching is postponed, the ship will be a ‘hoodoo’ vessel [a cursed or bad-luck ship]. If everything goes as smoothly for the Chester Sun as the launching went, she should be anything but a ‘hoodoo.’”

Dozens of orders kept the yard humming for years, especially from the company’s oil division, which drove Sun Ship’s engineers to constantly innovate their designs. They perfected the welded hull—lighter, and quicker to build than the riveted hull—and the double hull, which added a layer of protection against leaking.

When the Depression hit, orders for new ships slowed